How a Local Hydraulic Repair Service Diagnoses Issues

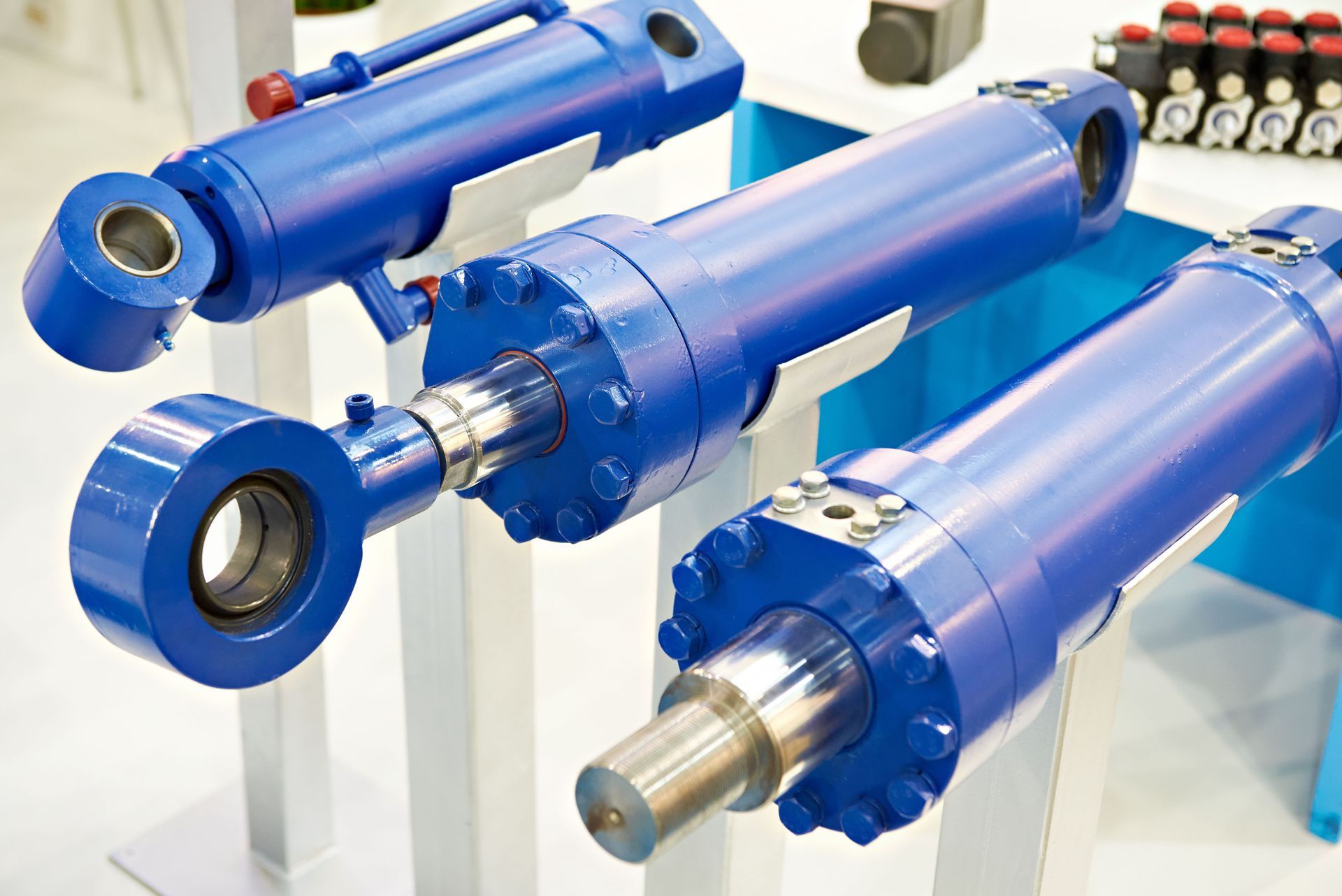

Hydraulic systems are the backbone of numerous industries, powering everything from heavy machinery to intricate automotive components. Given their complexity, diagnosing issues that arise in these systems requires expert knowledge and equipment. A local hydraulic repair service plays a crucial role in maintaining operational efficiency by employing expert techniques to identify and resolve problems. Understanding how these professionals diagnose hydraulic issues not only highlights their expertise but also underscores the importance of regular maintenance in preventing system failures.

Considering Comprehensive Inspections

The diagnostic process begins with a comprehensive inspection to identify obvious signs of wear and tear, leaks, or physical damage. Technicians use specialized tools designed to check pressure levels, as hydraulic systems operate based on specific pressure ranges. Any deviation from these parameters can lead to malfunctions. By comparing observed data against manufacturer specifications, professionals can pinpoint discrepancies that may indicate faulty components or require a system reset.

Utilizing Advanced Diagnostic Equipment

Beyond surface-level inspections, local hydraulic repair services utilize advanced diagnostic equipment to detect internal faults. According to Facts.net, Blaise Pascal, a brilliant French scientist, introduced Pascal’s Principle in 1647, forever changing the way we understand fluids and their properties. Understanding this principle allows technicians to trace pressure anomalies back to their source. By monitoring how pressure pulses through the system, repair experts can identify blockages, leaks, or failures in pumps, valves, and hydraulic lines.

Detecting System Problems with Fluid Analysis

Another critical aspect of hydraulic diagnosis involves fluid analysis. The cleanliness and composition of hydraulic fluid significantly impact system performance. By taking fluid samples and examining them for contamination, professionals can identify the presence of particulates or degradation in fluid quality. Such insights often indicate component wear or issues with seals and filters, guiding technicians towards the root cause of problems and helping in prioritizing repairs or replacements.

Diagnosing issues in hydraulic systems requires a methodical approach that leverages both technological tools and a deep understanding of fluid dynamics. Local hydraulic repair services are essential in identifying and resolving issues promptly, minimizing downtime, and ensuring that machinery operates efficiently. By anchoring their diagnostic processes in physical laws like Pascal's Principle, these services demonstrate how historical scientific insights continue to support present-day industrial operations. Contact Devine Hydraulics, Inc. today to speak with a professional hydraulic repair service!

Share On: